call us on 0207 594 3821

our qualified engineers are ready to helpLATEST NEWS

New non-combustible enclosure requirement for consumer units

The third amendment to BS 7671:2011 (IET Wiring Regulations Seventeenth Edition), which was published in January and comes into effect on 1 July, will include a new regulation requiring consumer units and similar switchgear assemblies in domestic premises to have a non-combustible enclosure.

The wording of the regulation is as follows:

421.1.201 Within domestic (household) premises, consumer units and similar switchgear assemblies shall comply with BS EN 61439-3 and shall: (i) have their enclosure manufactured from non-combustible material, or (ii) be enclosed in a cabinet or enclosure constructed of non-combustible material and complying with Regulation 132.12. NOTE 1: Ferrous metal, e.g. steel, is deemed to be an example of a non-combustible material. NOTE 2: The implementation date for this regulation is the 1st January 2016, but does not preclude compliance with the regulation prior to that date.

British Standard BS EN 61439-3, mentioned in the regulation, is entitled Distribution boards intended to be operated by ordinary persons (DBO).

Implementation date

As stated in Note 2 to the new regulation, the implementation date for the regulation is 1 January 2016. This is six months later than the effective date of Amendment 3 as a whole.

The purpose of the delay in implementation is to allow a period of co-existence of both metal- and plastic-enclosed consumer units and to allow time for manufacturers to work existing and new products through their supply chains. Nevertheless, as is also indicated in Note 2, the delayed implementation does not preclude compliance with the regulation prior to 1 January 2016.

Reason for the new regulation

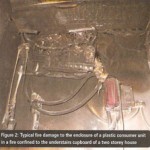

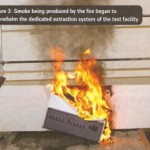

Regulation 421.1.201 was introduced because of reports from fire investigators of a recent trend of increasing numbers of fires involving consumer units having a moulded thermoplastic enclosure. See Figures 1, 2 and 3

The cause of the fires investigated was almost invariably found to be resistance heating as a result of poor electrical connections due to poor workmanship or lack of maintenance. Examples of such poor workmanship are thought to include:

- failure to tighten neutral conductor connections to the same torque as line conductor connections due to a misconception that neutral conductors carry less current;

- inadvertently taking cable insulation inside the terminal at a connection, resulting in the securing screw or the clamp of the terminal not making proper contact with the conductor;

- failure to check factory installed connections for tightness where required to do so by the manufacturer; and

- tightening connections to an incorrect torque and/or with inappropriate tools.

The crucial importance of checking that all electrical connections are properly made, and of taking remedial action where necessary, should never be forgotten.

Whilst the main cause of fire within plastic consumer unit enclosures is without doubt poor workmanship, other potential causes of fire within plastic consumer unit enclosures are thought to include:

- the type of internal components, such as where terminations have only one securing screw or are of the ‘cage clamp’ type); and

- where increased heat transfer to the enclosure is caused by the close proximity to an internal item, such as a neutral bar or a conductor terminated at the neutral bar and protruding above it.

Intent of the new regulation

The intent of Regulation 421.1.201 is considered to be, as far as is reasonably practicable, to contain any fire within the enclosure or cabinet and to minimise the escape of flames.

Requirements to be met by the non-combustible enclosure or cabinet

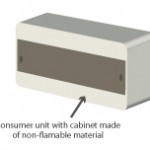

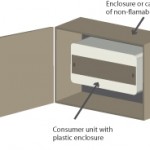

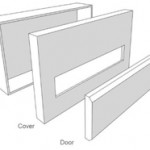

Regulation 421.1.201 gives the choice of either using a consumer unit (or similar switchgear assembly) having an enclosure manufactured from non-combustible material or using a consumer unit having an enclosure made from some other material, such as plastic, and installing it in a cabinet or enclosure constructed of non-combustible material. See Figures 4(a) and 4(b). In either case, certain requirements need to be met by the enclosure or cabinet, as explained below.

Figure 4 – The two ways to comply with enclosure requirements of Regulation 421.1.201

(a)

(b)

There is no published definition for the term ‘non combustible’ that aligns with the intent of Regulation 421.1.201. However, as stated in Note 1 to the regulation, ferrous metal, such as steel, is deemed to be an example of a non-combustible material.

Steel will no doubt be the material usually employed in the manufacture of the enclosure or cabinet. Nevertheless, it will be open to manufacturers to offer enclosures or cabinets made from other types of material that they claim to be non combustible within the intent of Regulation 421.1.201. In this case, however, the manufacturer would have to provide suitable evidence to support the claim of non combustibility, and it is not presently clear what criteria would be used to judge the non combustibility of a material other than non-ferrous metal.

The non-combustible enclosure or cabinet must provide a complete envelope (for example, base, cover, door and any components such as hinges, screws and catches) as necessary to maintain fire containment. All blanks, circuit-breakers and other devices must be contained within the non combustible enclosure or cabinet. Figure 5 shows an example.

Figure 5 – Example of non-combustible enclosure for consumer unit

Image reprinted with kind permission from Hager

Where the option of installing a plastic-cased consumer unit inside a non-combustible cabinet or enclosure is chosen, the non-combustible enclosure or cabinet must be arranged to afford adequate space for the initial installation and later replacement of individual items of electrical equipment. The non-combustible enclosure or cabinet must also allow access for operation, inspection, testing, fault detection, maintenance and repair, as required by Regulation 132.12.

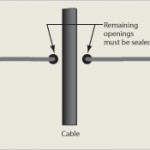

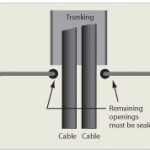

Sealing of wiring entries

It is important for the installer to seal all openings into the enclosure or cabinet for cables, conduits, trunking or ducting that remain after the installation of cables – see Figure 6. The intent of the sealing is to ensure that, as far as is reasonably practicable, any fire is contained within the enclosure or cabinet and the escape of flames to the surroundings of the cabinet or enclosure or into conduits trunking or ducting is minimised, as intended by Regulation 421.1.201.

Good workmanship and proper materials must be used, and account must be taken of the manufacturer’s relevant instructions, if any.

Figure 6 – Sealing of wiring entries

(a)

(b)

Similar switchgear assemblies

The phrase ‘similar switchgear assemblies’ in Regulation 421.1.201 means those assemblies used for the same fundamental application as a consumer unit. A consumer unit is defined in Part 2 of BS 7671:

‘Consumer unit (may also be known as a consumer control unit or electricity control unit). A particular type of distribution board comprising a type-tested co-ordinated assembly for the control and distribution of electrical energy, principally in domestic premises, incorporating manual means of double-pole isolation on the incoming circuit(s) and an assembly of one or more fuses, circuit-breakers, residual current operated devices or signalling and other devices proven during the type-test of the assembly as suitable for such use.’

An example of a similar switchgear assembly is a three phase distribution board that is intended to be operated by ordinary persons. This would have to have isolation that interrupts the three incoming line conductors and the neutral, rather than just double-pole isolation as mentioned in the above definition.

Consumer units in outbuildings or on the outside of a building

Regulation 421.1.201 uses the term ‘premises’. The question could therefore arise: do the requirements of the regulation apply to a consumer unit or similar switchgear assembly within an outbuilding such as a garages or shed, or mounted on the outside or a building?

Some dictionary definitions of ‘premises’ are ‘a house or building, together with its land and outbuildings’ and ‘the land and buildings owned by someone’.

However, Regulation 421.1.201 was principally introduced to cover the interior of a household building and any garage or other outbuildings integral, attached, or in close proximity to that building.

Doubt could exist about whether or not a particular outbuilding could reasonably be considered to be in ‘close proximity’ to the household building. A way of resolving this might be to make a judgement of the likelihood that fire originating inside the enclosure of a consumer unit or similar switchgear in the outbuilding might lead to the outbreak of fire in the household building or in any outbuilding integral or attached to it. Relevant factors to consider about such an outbuilding might include whether or not that building or its expected contents are highly combustible.

Regulation 421.1.201 is not intended to apply to a consumer unit or similar switchgear assembly that is not within a building, such as a consumer unit mounted outdoors on the outside of a building.

Residential premises such as care homes

The regulation is not intended to apply to consumer units and similar switchgear assemblies in residential care homes or other premises not intended for household use. The concerns leading to the Regulation 421.1.201 being introduced related specifically to domestic premises, which are not covered by fire safety legislation in the way that premises such as care homes are. The regulation therefore uses the term ‘domestic (household) premises’.

Wiring Matters interviewed Charlie Pugsley, London Fire Brigade investigator, about the fire-related changes made by Amendment 3.